Furniture production

Artisanal furniture production

Woodworking shop for interior design furniture, personalised and custom-made

We, at Garbo Arredamenti, consider ourselves woodworking artisans who have become real “design” woodworkers creating solutions for every space, be it commercial or residential.

We can develop complex, design projects thanks to our simple, flexible and rapid internal department which facilitates communication between departments and experts, without any bottlenecks. We handle the entire process: design, presentation of prototypes, production of every single furnishing detail and assembly.

Perfect wood cutting

Veneer cutting machine

Useful for working raw-purchased veneers. The precisions blade is a able to cut bundles of veneers of any type, and once butted and regulated, they can be jointed to cover any type of panel.

Squared and retouched to perfection

Bench saw

The precise cut of any type of support, be it wooden or not, in semi-manual mode, is done with this machine. The pieces are squared and/or retouched to get the exact size in length and width, as well as to obtain angle cuts of the chosen material.

Custom profiles

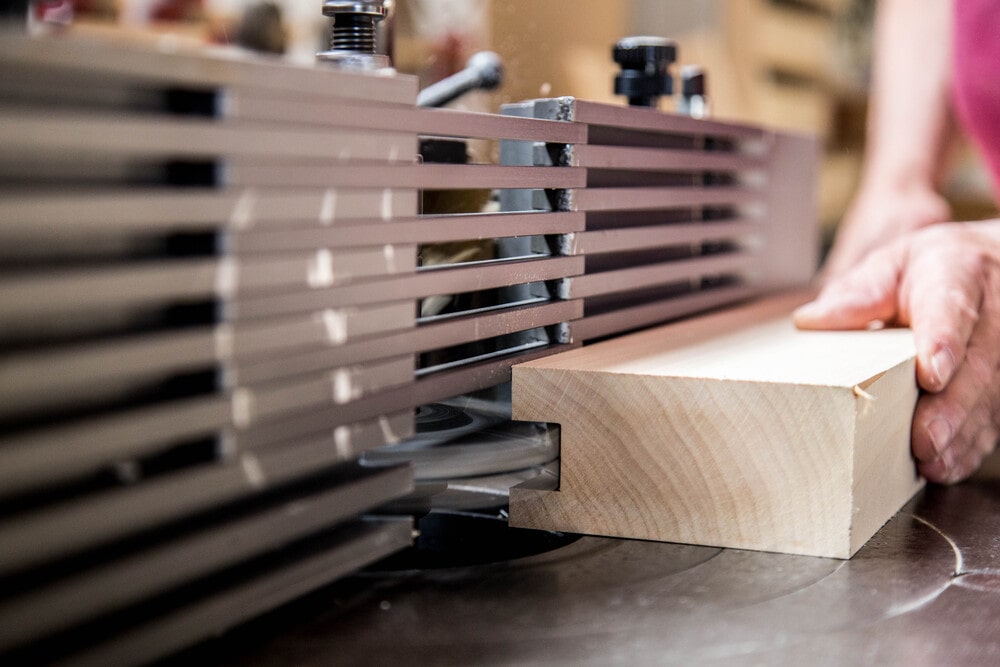

Spindle moulder

With this machine, composed of a rotating shaft on which a milling cutter is mounted, it is possible to obtain every type of profile by removing the material with the use of a rotating blade. We have a wide range of milling cutters available, but we are also able to produce specially made cutters to adapt to our clients’ custom, profile needs.

Wood that is perfectly smooth to the touch

Sanding machine

The use of different-grained, abrasive paper allows us to hone the product to the point where it is “soft” to the touch. Passing solid wood through this machine is fundamental for the best result on the finish of the product.

Cutting of different materials

Vertical cutting saw

Based on the blade, we can cut different materials from wood to plastic, to aluminium. It is used after the spindle moulder to butt the profiles to size.

Uniform reduction of wood thickness

Calibrating machine

Any panel element inserted in this machine is reduced to the thickness requested by the client, or by technical needs for production and assembly. The piece is inserted on one side and, by sanding the surface, it comes outs on the other side with the proper measurements.

Wood roughing

Panel saw

Any type of solid wood can be found in different shapes. Most times it is best to purchase it in the rawest form possible to be able to adapt it to the project of the moment. The panel saw is one of the first machines that starts the roughing of the wood with the use of an ultra-resistent blade and a very powerful motor which reduce the thickness of the wood.

Uniform reduction of wood thickness

Biesse Rover A

Even though it is a timeworn machine, it is surely one of the most “modern” pieces in the workshop. A 3-axis numerical control machine with accessories means being able to work 90% of the necessary machining on panels with bits, blades and cutters. The furniture elements are “exploded” into single pieces which will be squared, drilled, milled.

Multipurpose hand tool

Rubber hammer

There are many machines in Garbo’s carpentry workshop, but the totally manual tools are never missing, such as the hammer, symbol of hard work and craftsmanship.

Wood edging for a perfect finish

Automatic edgebander

Most panels pass through this machine which applies a wooden or plastic edge to protect the thickness of the wood during the finishing phase. The material is applied, glued, trimmed. The operator only needs to chamfer it by hand for a detail of the edge to perfection.

5-axis technology

CNC BIESSE ROVER B

The latest jewel in Garbo Arredamenti: this 5-axis numerical control machine allows us to execute 99% of the machining. With the proper high level, technological know-how, we can customise every design product. 3D technology, automatic panel loader, nesting systs and automatic labelling of the pieces give this machine an unfathomable potential.